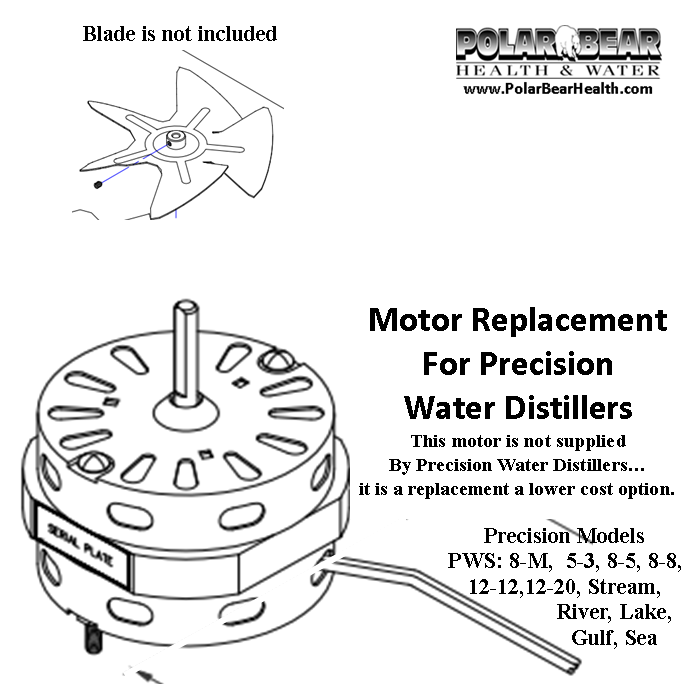

Motor – Precision Water Distillers Universal Replacement R203

Replacement Motor, spins the fan blade to cool steam, for Precision Water Distillers. May fit other brands of distillers.

New Motor for 2024 – 1600 RPM, 115V, HP1/70, 0.8 Amps, Rotation Clockwise spin, Black body measures 3.3″ diameter x 2″high – includes 2 electrical wire connectors (2 wires come off this motor) ** This motor may not be exactly like your old one… considering Precision Water Distillers were made since 1999 … many motors over the years have been used… This motor can be used with any age or model of distiller. If you have a plastic blade we recommend you order a new blade. If metal.. most can be reused. but sometimes they metal blades can cause noise and vibration.. in that case replace the metal blade also.

NOTE** this motor uses 1/4″ threaded shaft – there is a flat spot – this is where you tighten the screw for the metal blade!!

This is a universal motor replacement for all Precision Water Distillers residential 26 & 42 model distillers. 8-M, 5-3, 8-8, 12-12, 12-20, Stream, River, Lake, Gulf, Sea

Fan Motor – Heat is the motor’s greatest enemy. Make certain air passages in both the motor and in the distiller are kept open and clear of lint. Blow or vacuum motor and cooling coils regularly.

If you cannot get this motor to sit flush – remove both nuts from the bottom of the motor, then install the motor, but when you tighten the nuts to the distillers frame, make sure the screw mounts are in place. Hand turn the fan blade to make sure it is reinstalled at the correct height, make sure fan blade is installed correctly, so it scoops the air. Don’t install blade upside down as blade will not cool properly. Make sure blade does not hit the coils.

Tools Required

- 11/32” Nut Driver or small Adjustable Wrench (Crescent Wrench)

- Electrical Terminal Crimping Pliers

- Wire Cutters

- #2 Phillips Screwdriver

- Red Robertson Screwdriver

- 1/8” Hex wrench (Allen Key)

- Needle Nose Pliers

- Flat Head Screwdriver

Assembly Instructions

1.Ensure that all of the parts that you require are available to you.

2.Turn main power switch on distiller off and drain the boiler tank. CAUTION: DRAIN VALVE MAY BE VERY HOT. Unplug cord from wall plug and wait at least 1 hour for distiller to cool.

3.Remove the Distiller covers. This may require disconnecting the water feed line, if you do so ENSURE THE SADDLE VALVE IS CLOSED BEFORE DISCONNECTING WATER FEED LINE.

Using the hex (Allen) wrench, remove the set screw attaching the fan blade to the old motor and slide blade up & over motor shaft. This may require GENTLY lifting the condenser coil. BE CAREFUL NOT TO BEND THE FAN BLADE OR COIL. Keep the fan blade and screw for reassembly.

Using the wire cutters, cut the old motor wires, keeping the length… do not shorten.

Remove the old motor. Using the wire strippers on the crimping pliers, remove about 3/8” of insulation from the end of each wire.

Insert the new motor in the distiller body and reattach with the new kep nuts. Use wire nuts to fasten the new motor wires to the old motor wires, so that you are attaching the wires coming off the new motor to the wires that are installed already on the old motor. Ensure the wires do not interfere with fan blade motion.

Note Precision Distillers and Polar Bear Distillers— both manufactures use Aluminum blade. Clock wise spin. *make sure blade is mounted with the hub and set screw to the topside

Reattach the fan blade to the motor. Blade height must be adjusted so that there are no obstructions during rotations. Turn blade by hand to check for obstructions. Make sure you line up the flat part of the motor shaft with the set screw of the blade. Note Precision Distillers and Polar Bear Distillers—both manufactures use motors that have 1/4″ shaft “Notice the flat spot” Tighten the set screw from the blade to threaded flat spot on the motor shaft.

Tighten the blade. Reattach covers. Ensure impurities drain valve is closed. Reattach water feed line if it was removed and open saddle valve.

The distiller should now operate properly. If it does not, confirm that the wires are connected to the proper location by referring to your electrical schematic.

If they appear correct, we suggest you take your distiller to an authorized service representative, or call 1-780-477-1328 ask for service.

Water Distiller Parts | Precision Water Distiller Parts | Fan Motor | Cooling Motor | Health Food Stores Edmonton | Natural Food Stores Edmonton | Supplement Stores Edmonton | Health Supplement Stores Edmonton | Best Supplement Stores Edmonton | Aromatherapy Stores Edmonton | Vitamin Stores Edmonton | Herbal Stores Edmonton| Distiller Stores Edmonton | Reverse Osmosis Water Filters Edmonton | Water Pumps Edmonton | Water Pumps for Sale Edmonton

Reviews

There are no reviews yet.